Chilling Logistics: Ensuring Vaccine Integrity through Reliable Cold Chain Equipment

Vaccines safeguard public health and save countless lives worldwide. By preventing infectious diseases, vaccines have dramatically reduced mortality rates, especially among vulnerable populations such as infants, elderly individuals, and people with compromised immune systems.

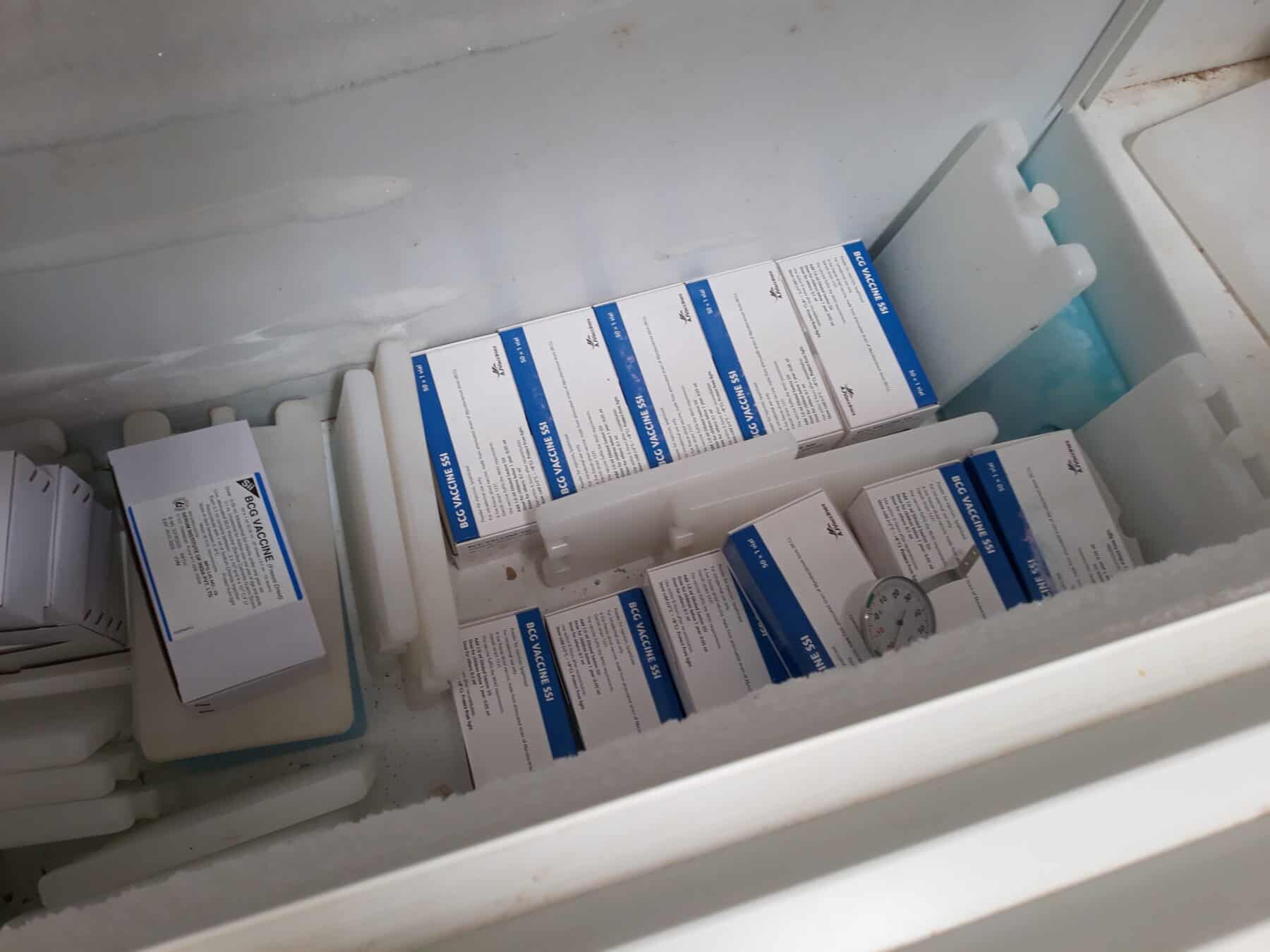

A unique aspect of vaccine management is keeping the vaccines cold throughout the supply chain, from the manufacturer until they are administered into arms in the most rural health facilities. Cold chain equipment (CCE) is required for this, and the technology has improved over the years, including through the introduction of solar-powered equipment, freeze-free vaccine carriers, and remote temperature monitoring devices. These have all contributed to more reliable CCE with fewer temperature excursions, and, by extension, to maintaining vaccine quality.

One thing that remains the same, however, is the need for maintenance to ensure that CCE continues to work and vaccines are in the ideal temperature range. This involves preventive maintenance such as defrosting and maintaining good air flow inside and around the equipment, as well as corrective maintenance, which is typically more technical and involves changing spare parts.

For forty years, JSI has been working closely with ministries of health and immunization programs around the world to provide technical assistance for CCE planning and management. We work closely with Expanded Program on Immunization (EPI) logistics teams to update CCE inventories; shape the planning and prioritization exercise for new CCE; support use of data from temperature monitoring devices; and design maintenance systems that respond to country needs.

Our country-level practical experience and insights contribute to regional and global guidance and policies.

At the country level, we work closely with all partners supporting cold chain work to ensure alignment and focused efforts without duplication. At the global level, we contribute to cold chain management and maintenance through the Immunization Supply Chain Steering Committee (iSC2) and work with partners such as PATH, VillageReach, CHAI, UNICEF, WHO, and Gavi the Vaccine Alliance.

Areas of Expertise

We create and manage systems to respond to the true needs of the immunization program. Our team uses human-centered design to uncover maintenance system performance drivers and works with maintenance technicians to design tailored solutions.

We support introduction and use of remote temperature monitoring devices in multiple countries, with a focus on making temperature actionable and accessible to maintenance technicians.

We introduce optimized approaches to update CCE inventory, and integrate the data into existing systems and structures, including the energy consumption aspect to link to broader infrastructure planning.

As part of the iSC2, our team contributes to Gavi’s strategy and elevates the importance of CCE maintenance for funding and strategic direction.

Expertise Spotlight

Cold Chain Maintenance

Cold chain maintenance is important to ensure CCE performance and vaccine quality. With new technology, approaches, and insights into cold chain equipment and maintenance systems, cold chain technicians are better able to respond to equipment failures. To support equipment repair efforts, JSI brought maintenance technicians, data analysts, and supply chain managers from six countries together in Nairobi to tackle a mutual challenge: how to plan for and streamline maintenance of cold chain equipment in remote clinics in Africa. In collaboration with New Horizons, PATH, VillageReach, CHAI, eHealth Africa, and the USAID MOMENTUM Routine Immunization Transformation and Equity project, JSI gathered cross-national teams to map out cold chain systems processes, identify challenges, resolve issues, and share experiences. Designed for the men and women who fix cold chain equipment and understand the inner workings of that equipment, the event generated shared insights and solutions.